Printing with Nylon Carbon solves manufacturing issues

The Italian company Promotion SpA, a partner for many Swiss luxury watchmakers, has solved several prototyping issues by incorporating 3D printing into their tooling with Nylon Carbon filament on their INTAMSYS HT 3D printer. “We were positively impressed by its mechanical resistance and lightness“, says Federica Tiso.

Promotion SpA is a well-known supplier to the luxury jewelry and watches industry. The company in Vicenza, the main Italian center for the gold jewelry and watchmaking components industry, has become an important partner for those brands when it comes to the manufacturing of watch bracelets and accessories. “We control the entire process”, says Federica Tiso, R&D Material Scientist at Promotion Spa. “From design and prototyping, through manufacturing, quality control, and logistics. Together with the competence and the skills to develop and manufacture customized bracelets, we can offer our customers a complete solution.”

3D printing since 2014

Promotion SpA has embraced 3D printing to shorten the development time and ensure the quality of each bracelet, and in 2014 they bought their first SLM-machine for 3D printing bronze and steel, both for prototyping and tooling. They then acquired a second 3D metal printer, specifically for printing with pure gold. In 2019 the first DLP-printer was introduced at the Promotion facility, to create tooling from liquid resins. Federica explains: “Our products are highly customized and manufactured in small batches. This leads to the need to change often the tools used for assembly or polishing. Every bracelet undergoes a very tough quality and mechanical test, so we also need tools to simplify this important step.” Each tool has unique requirements. Tools for lab tests must withstand an extremely high number of cycles without warp or breakage. Polishing tools cannot be spoiled too fast and assembly tools must have a smooth surface to avoid scratches on the workpieces.

Why choose Nylon Carbon filament?

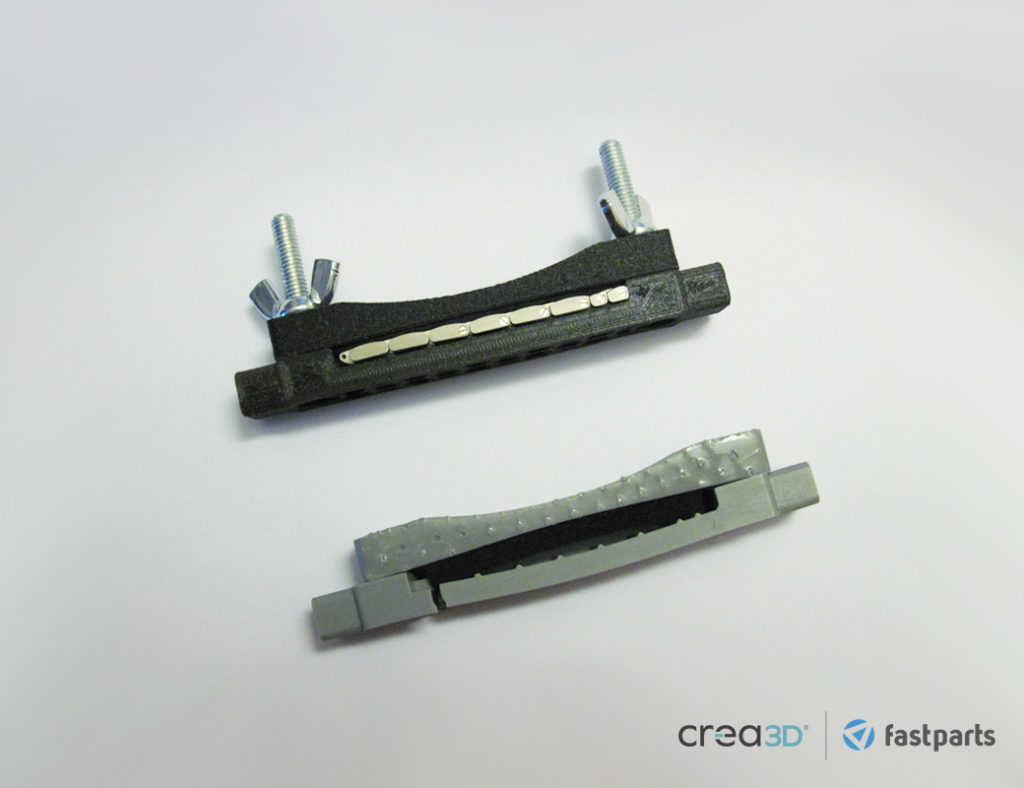

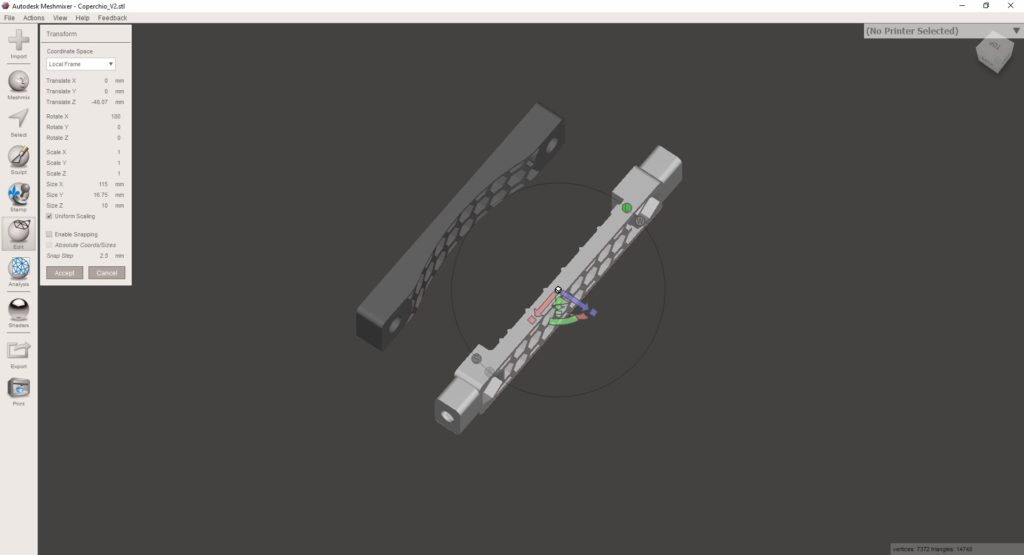

Promotion had some issues with a 3D printed fixture used to align the links of a bracelet for side welding. The overall dimensions of the tool were 115×16.75×10 mm. The width of the teeth were approximately 0.8 mm. Federica says: “To protect the bracelets from friction with the tool and at the same time to avoid them to move, we use a soft material that allows us to connect the two parts strongly without causing any damage. But this solution creates a stress in the middle of the tool that leads to breakage.”

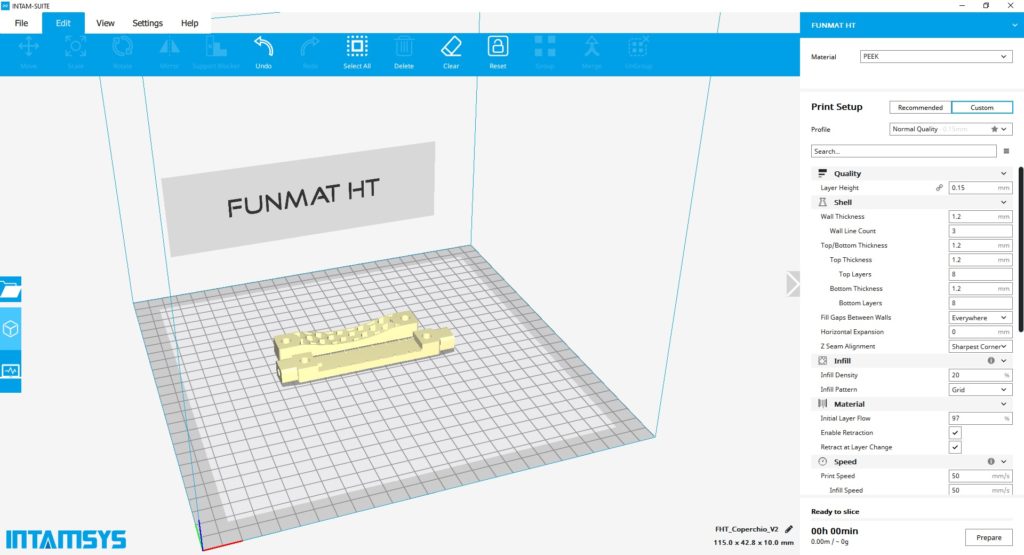

The tooling was easy to break when too much force was applied, while the polymers in the resin suffered from photodegradation, which made the printed parts weaker. Therefore Federica teamed up with FastParts to find a solution. The engineers at FastParts (a printing service department of Crea3D) suggested 3D printing the tool with a high-performance polymer like Nylon Carbon on the INTAMSYS FUNMAT HT FFF printer. It is the entry-level system of a line of industrial high-temperature 3D printers from INTAMSYS. The INTAMSYS FUNMAT HT printer enables you to 3D print high-performance materials such as Nylon Carbon filament (a material with excellent mechanical properties for tooling and similar applications).

A true success story

“We have never had the opportunity to use materials like this, but we were positively impressed by its mechanical resistance and lightness. The parts printed by FastParts endure many cycles of fixing the lateral screws. Although the tooling is loaded, it does not warp in the middle”, says Federica about the results. Promotion engineers designed small teeth (with a width of 0.8 mm) for quick and easy alignment of the bracelet from the original 3D model. Because FFF printing is less detailed than printing with resins, they had to change the design slightly. “The only other thing we had to do, is to remove some burs after printing. That’s all.”

Replacing metal with polymers

INTAMSYS 3D printers have proven themselves to be of great value for Promotion, especially because printing tools with high-performance polymers can replace metal, the next step they are pursuing. The tough but light parts printed with Nylon Carbon filament are a great solution to create a lightweight and wear-resistant end of arm tooling for the robot wrist. “We are looking forward to exploring more opportunities together with FastParts.”

Crea3D website: www.crea3d.com

FastParts website: www.fastparts.it