Learn how and why they adopted 3D printing to bring their business to another level

Located in the surroundings of Venice, Italy, WEERG was established in November 2015.

The company is the result of its owner’s dream, Matteo Rigamonti, and has become over the years a leader printing service bureau and one of the most popular online quote estimators. Discover WEERG’ journey and their collaboration with INTAMSYS.

The company started with CNC machining services. Indeed, not such a long time ago, getting CNC parts delivered as well as getting a quote for CNC parts were exhaustive processes. Matteo decided to establish a company that would answer his needs.

The company’s goals are to offer – easy, – online quotations through their website and – fast delivery of the parts (within 3 days), putting back the client’s satisfaction first.

They receive on average up to 20,000 quotes a day!

It is so popular that many companies even use their quote system to make their own benchmark. Thus, WEERG never sleeps.

What about 3D printing?

When the company started in 2016, “volume production” was still not so ready for the 3D printing industry. WEERG did not believe in 3D printing mass production alone at that time for generating enough profit, thus they started with CNC machines mainly.

3D Printing volume production at WEERG started with the investment in a fleet of HP Jet Fusion 5210. They saw potential, a good cost/product quality, and they considered HP as an honest partner. Adding 3D printing allowed them to offer PA11, PA12, PP, and even PA12 + GlassBeads for their customers’ applications. An average of 24 to 25,000 pieces a day are being printed on these printers.

Having CNC, 5-axis continuous milling machines, and Jet Fusion 3D Printers that work 24/7 allows them to offer 3 choices of aluminum, 3 types of steel, and polymers like nylons. The business grew fast and with more than half of the sales turnover coming from overseas.

Why go for a high-performance FFF 3D printer?

Demand kept on growing and more and more requests came from industrial companies asking for polymer parts. Polymers parts that have different properties like:

- Flame retardancy

- High chemical resistance

- High-temperature resistance

- High stiffness at high temperature

- High electrical insulation

- Hydrolysis resistance

- Etc.

Fabio Trotti, 3D R&D Manager explained, “our clients are really curious about high-performance materials and about how they can use them in their company. The innovation of AM is stimulating Product Designers that work with us to develop in a new way driving innovation forward.”

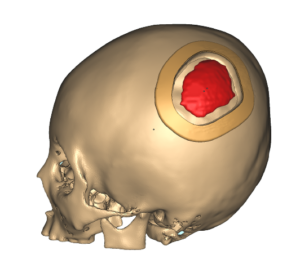

Though WEERG already had some resign printers to tackle medical and model-making business, completing their portfolio with high-temperature 3D printers capable to print polymers like PEEK, PEEK-CF, PEEK-GF, etc. became a need.

After a thorough search, several benchmarks, and contacts made with local and international printer manufacturers, the supplier choice was INTAMSYS.

“We were looking for printers that can print high-performance materials and which could run 24/7 on our production floor. We look meticulously for suppliers that can help us deliver functional industrial parts to our clients.”, said Matteo, WEERG’s founder, and CEO.

INTAMSYS offered one single solution that got it all:

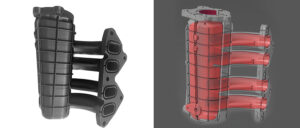

- a robust printer with a nice esthetic finish with a heated chamber, dual heated nozzles, and heated filament chamber.

- a free and user-friendly software with incorporated printing settings (Click and Print experience) on a wide range of materials (from PA12-CF to PEEK),

- a reliable support and what we like most at WEERG, honesty and a true partnership

Discover WEERG’s journey with INTAMSYS’ printers

PEEK part – Prototype gear for testing and validation – Quick turnarounds are key in the prototyping phase to allow for easy iteration before finalizing the geometry.

PEEK annealed part – Carter/sump for a small high-performance engine – Lighter than its metal machined counterpart, can fulfill its duties thanks to the high mechanical and thermal properties of PEEK.

PA12-CF part – GoPro helmet mounting bracket. Very light weight, rigid and high performance to reduce fatigue and unnecessary weight on the rider.

“The INTAMSYS FUNMAT PRO 410 has been a performant and reliable tool since day one. It allows us to process high-performance polymers that enable our customers to innovate with them in highly loaded, thermally challenging, and metal replacement applications. It gives us the confidence that is needed to print 24/7 unattended with long print jobs of 100+ hours. It redefines what can be achieved with FDM technology”, stated Fabio.

The story has just begun!

WEERG S.r.l

Via Campocroce, 14

30037 Scorzè (VE) Italy

info@weerg.com

- Website: https://www.weerg.com/en/global/home

- Facebook: https://www.facebook.com/weerg.it

- LinkedIn: https://www.linkedin.com/company/weerg/

- Twitter: https://twitter.com/Weerg9