3D printing is becoming an increasingly key technology for the Royal Netherlands Navy. With the INTAMSYS 3D printing of parts on frigates, they will be less dependent on complex logistics operations.

They have been using the FUNMAT PRO 410 for parts printing. It supports fire resistance and strong materials, also can withstand temperatures up to 150°C without issue.

This year, the Navy has revealed how it continues to use INTAMSYS printers for a variety of tasks, printing replacement parts in high-performance materials like PEKK-CF. This article looks at three ways the Royal Netherlands Navy deployed the FFF 3D printers to support on-land troops during a military exercise in Suriname.

Amplifier brackets

Most consumer-level FFF 3D printers cannot print brackets capable of supporting exceptionally heavy weights. Common filaments like PLA and ABS are durable enough for prototypes and low-impact applications, but it takes a much stronger material to guarantee high performance in the heat and humidity of Suriname.

During the military exercise in South America, crew members needed brackets to support a 20 kg signal amplifier so it could be mounted near the top of a 25-meter pole. Doing so would reduce the need to use long cables and consequently boost the signal of the antenna on top of the pole. Since the crew didn’t have brackets with them, they used an INTAMSYS printer to make some out of PEKK-CF, a high-performance material that requires a high-temperature 3D printer with extrusion temperatures of at least 350 °C. Weaker materials could buckle under heavy weight and would not be safe to use.

Valve wheels

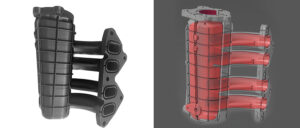

A naval ship or submarine contains a huge number of valves for regulating pressure and fluid flows. Such valves control the flow of fresh water, ballast water, and liquid for hydraulic systems, among other things. Valves have wheels that allow them to be manually adjusted, and these valve wheels are regularly removed for cleaning and maintenance. However, they sometimes break or get lost, which means ships must carry spares.

Because there are so many different types and sizes of valve wheels, DMI workers have been using their INTAMSYS 3D printers to fabricate wheels on demand rather than carrying a huge number of prefabricated aluminum/steel spares on board. Valve wheels printed in high-strength materials do not overheat and can last a long time; some are even installed permanently.

Orthotics

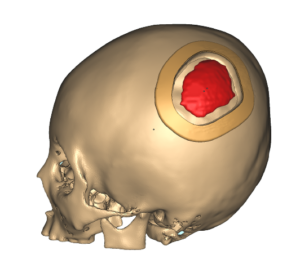

Ships and machines aren’t the only things that require maintenance on long missions. Crew members can suffer minor and major injuries in the field, and ships aren’t always within reach of a medical center.

The DMI’s additive specialists have been working with the Radboud University Medical Center (part of the Radboud University Nijmegen) on a research project for developing custom orthotics. Using a mobile 3D scanning application developed by Belgian company Spentys, technicians can design and 3D print custom-fit orthotics to treat minor injuries. A variety of materials can be used, including PEKK, ABS, and PP, and the tightness of the devices can be altered over time with adjustable straps as the injury heals.